Product development

Introduction

An architecture is great, but without real-world applications and products, it doesn’t have much practical value. That’s why at Be-Rex, we develop models and prototypes to prove the validity of the STaR architecture. This helps us build practical knowledge and expertise while easing concerns among potential partners and end-users.

Product development approach

At Be-Rex, we take a step-by-step approach to product development, starting with turbines, then moving on to pumps and finally generators. By increasing complexity gradually, we can quickly identify what works and what doesn't. Minimizing unnecessary costs.

We work with a dedicated team and select suppliers to develop our models and prototypes in a set order.

Model development proces

- STaR Architecture

- CAD designs

- Simulations

- Thermodynamic simulations (power output)

- Friction analysis

- Flow analysis

- FEM (Finite Element Method) analysis for structure

- Component manufacturing

- Custom STaR parts

- Generator parts (frameless motor)

- Power electronics parts (direct current)

- Assembly and testing

Laboratory

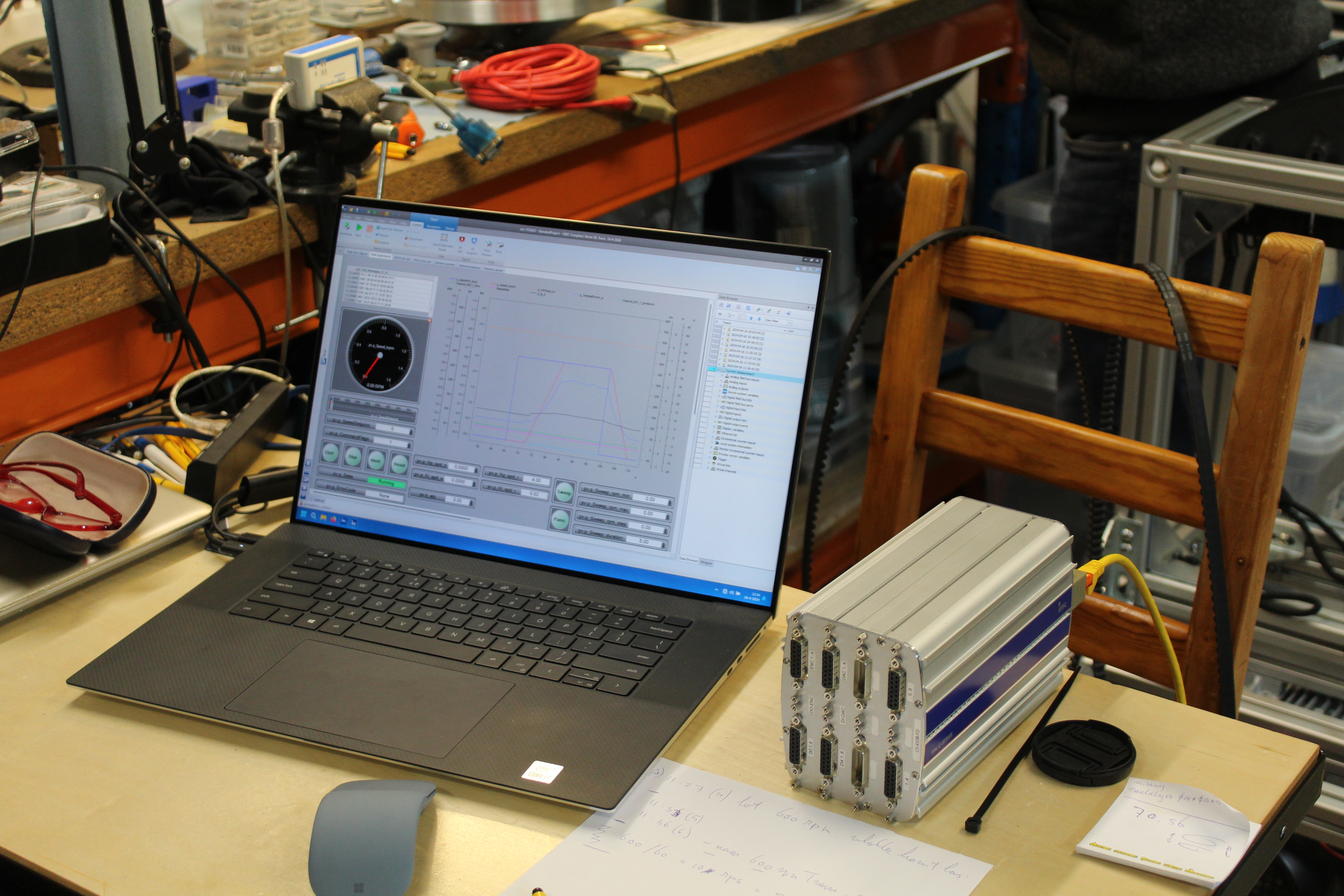

Once assembled, we test our models and prototypes in our in-house laboratory, which is centered around a comprehensive testing system. This allows us to gather all data in one place for thorough analysis.

Test bench

- Power electronics module (Can-Bus)

- Motor management module (Can-Bus)

- Additional sensors for:

- Pressure

- Temperature

- Flow rate

Key insight

Through our development process, we've learned that the seals and friction between STaR components are crucial, as they significantly impact efficiency. We’ve documented and patented our solutions to protect our investments and those of our potential partners.

Contact CEO and Founder, of Be-Rex B.V., Pim Bekking to learn more about this opportunity.

T: +31 6 2722 8518 | E: pim@be-rex.com